Confused about license plate screw sizes? This comprehensive guide covers everything you need to know. From metric to standard sizes, factors to consider, troubleshooting tips, and proper installation techniques, we’ve got you covered.

Understanding License Plate Screw Sizes

License plate screws may seem like a small detail, but choosing the right size is crucial for proper installation and security. License plate screw sizes can vary, so it’s important to understand the differences between metric and standard screw sizes.

Metric Screw Sizes

Metric screw sizes are commonly used in many countries around the world, including Europe and Asia. These screws are measured in millimeters (mm) and are designated with an “M” followed by a number. For example, M6 and M8 are two common metric screw sizes used for license plates.

- M6 Screws: M6 screws have a diameter of 6mm. They are commonly used for smaller license plates and are suitable for most standard vehicles. These screws are relatively easy to find and are compatible with various license plate frames.

- M8 Screws: M8 screws have a diameter of 8mm. They are larger and more robust compared to M6 screws. These screws are typically used for larger license plates or when extra strength is required. M8 screws provide a secure attachment and are suitable for heavy-duty applications.

Standard Screw Sizes

In the United States, standard screw sizes are often used for license plates. These screws are measured in inches and are designated with a number followed by a hashtag (#). For example, #14 screws are commonly used for license plates.

#14 Screws: #14 screws have a diameter of approximately 0.242 inches or 6.15mm. These screws are relatively larger and provide a strong attachment. They are commonly used for standard license plates and are compatible with most vehicles.

Understanding the difference between metric and standard screw sizes is essential when choosing the right screws for your license plate. It’s important to note that the size of the screw holes on your license plate and vehicle may vary, so it’s crucial to measure them accurately before purchasing screws.

To determine the correct size, you can use a measuring tool such as a caliper or ruler. Alternatively, you can consult your vehicle manual or contact the manufacturer for recommendations.

It’s also worth mentioning that some license plate frames or holders may come with pre-drilled holes, specifically designed for certain screw sizes. In such cases, it’s important to ensure that the screws you choose match the pre-drilled holes on your license plate frame.

By understanding the differences between metric and standard screw sizes, you can make an informed decision when selecting the appropriate screws for your license plate. Whether you opt for metric or standard screws, it’s important to choose high-quality screws that are durable, corrosion-resistant, and compatible with your license plate and vehicle.

In the next section, we will explore the factors to consider when choosing license plate screws, including vehicle manufacturer recommendations, material and strength, and anti-theft features. Stay tuned!

Factors to Consider When Choosing License Plate Screws

Choosing the right license plate screws goes beyond just selecting the correct size. Several factors should be considered to ensure a secure and reliable attachment. In this section, we will explore the key factors to keep in mind when choosing license plate screws.

Vehicle Manufacturer Recommendations

Vehicle manufacturers often provide recommendations for license plate screw sizes and types. It’s important to refer to your vehicle manual or contact the manufacturer to determine the specific requirements for your vehicle. Following the manufacturer’s recommendations ensures compatibility and reduces the risk of damage to your vehicle.

Material and Strength

License plate screws should be made of high-quality materials that are resistant to rust and corrosion. Stainless steel screws are a popular choice due to their durability and resistance to environmental factors. Additionally, consider the strength of the screws. Depending on your vehicle and the location of your license plate, you may need stronger screws to withstand vibrations and ensure a secure attachment.

Anti-Theft Features

License plate theft is a common issue, and choosing screws with anti-theft features can help prevent such incidents. Anti-theft screws typically require specialized tools for installation and removal, making it more difficult for thieves to tamper with your license plate. These screws often have unique heads or designs that deter unauthorized access.

When selecting license plate screws, it’s important to consider these factors to ensure a proper and secure installation. In the next section, we will explore common license plate screw sizes, including M6 screws, M8 screws, and #14 screws. Let’s dive in!

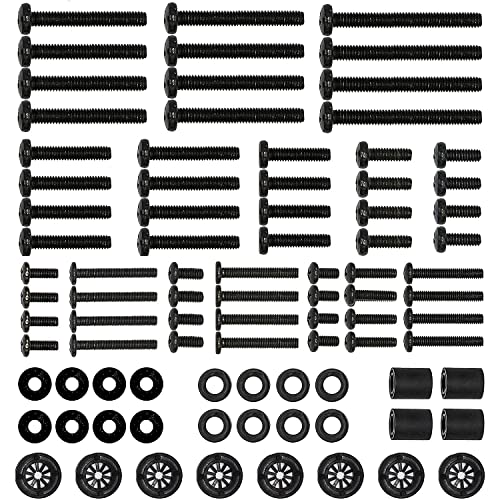

Common License Plate Screw Sizes

License plate screws come in various sizes to accommodate different license plate dimensions and vehicle requirements. In this section, we will take a closer look at three common license plate screw sizes: M6 screws, M8 screws, and #14 screws.

M6 Screws

M6 screws have a diameter of 6mm and are commonly used for smaller license plates. They are suitable for most standard vehicles and provide a secure attachment. M6 screws can be easily found in hardware stores and are compatible with various license plate frames.

To install M6 screws, you will need a suitable screwdriver or a socket wrench that fits the screw head. Apply firm pressure while turning the screws clockwise to ensure a tight and secure fit. Be cautious not to overtighten the screws, as it may damage the license plate or the vehicle’s mounting surface.

M8 Screws

M8 screws have a diameter of 8mm and are larger and more robust compared to M6 screws. They are typically used for larger license plates or when extra strength is required. M8 screws provide a secure attachment and are suitable for heavy-duty applications.

To install M8 screws, you will need a larger screwdriver or socket wrench that fits the screw head. Similar to M6 screws, apply firm pressure while turning the screws clockwise to ensure a secure fit without overtightening.

#14 Screws

14 screws are commonly used in the United States for license plates. They have a diameter of approximately 0.242 inches or 6.15mm. These screws provide a strong attachment and are compatible with most standard license plates.

To install #14 screws, you will need a suitable screwdriver or socket wrench that fits the screw head. Apply firm pressure while turning the screws clockwise to ensure a secure fit. Avoid overtightening, as it may damage the license plate or the vehicle’s mounting surface.

Now that we have covered the common license plate screw sizes, let’s move on to the next section, where we will discuss how to determine the correct license plate screw size. Stay tuned!

Factors to Consider When Choosing License Plate Screws

When it comes to choosing the right license plate screws for your vehicle, there are several factors that you should take into consideration. By understanding these factors, you can ensure that you select the most suitable screws for your specific needs. In this section, we will explore three important considerations: vehicle manufacturer recommendations, material and strength, and anti-theft features.

Vehicle Manufacturer Recommendations

One of the first things you should consider when choosing license plate screws is the recommendations provided by your vehicle manufacturer. Different car manufacturers may have specific requirements or guidelines for the type and size of screws that should be used to attach license plates. These recommendations are often included in the vehicle owner’s manual or can be obtained from the manufacturer’s website or customer service.

By following the manufacturer’s recommendations, you can ensure that the license plate screws you choose are compatible with your vehicle. This is important because using the wrong screws can lead to issues such as stripped threads, loose plates, or even damage to the vehicle’s body. Additionally, using the recommended screws may be necessary to comply with certain warranty or safety regulations set by the manufacturer.

Material and Strength

Another factor to consider when selecting license plate screws is the material and strength of the screws. License plates are exposed to various weather conditions and may undergo frequent vibrations while driving, so it’s crucial to choose screws that are durable and resistant to corrosion.

Common materials used for license plate screws include stainless steel, zinc-plated steel, and nylon. Stainless steel screws are known for their excellent corrosion resistance, making them suitable for use in areas with high humidity or salt exposure. Zinc-plated steel screws offer good corrosion resistance and are often more affordable. Nylon screws are lightweight and non-corrosive, but may not be as strong as metal screws.

In terms of strength, it’s important to choose screws that can securely hold the license plate in place. The strength of a screw is typically determined by its thread size and pitch. Thicker screws with a larger thread size, such as M8 screws, are generally stronger than thinner screws like M6 screws. Additionally, screws with fine threads provide better holding power than screws with coarse threads.

Anti-Theft Features

Anti-theft features are another consideration to keep in mind when choosing license plate screws. License plate theft is unfortunately a common occurrence, as thieves can easily remove plates and use them for fraudulent activities or to avoid detection. To prevent this, there are license plate screws available that incorporate anti-theft measures.

One popular type of anti-theft screw is the tamper-resistant or security screw. These screws have unique drive designs that require specialized tools to install or remove them. The unconventional shape of the screw heads makes it difficult for thieves to tamper with or remove the license plates without the correct tools.

Additionally, some license plate screws come with caps or covers that conceal the screw heads once they are installed. These caps not only provide a cleaner appearance but also act as a deterrent to potential thieves, as they make it less obvious that the screws can be easily accessed and removed.

Considering the recommendations of your vehicle manufacturer, the material and strength of the screws, and the availability of anti-theft features will help you make an informed decision when choosing license plate screws. By selecting the right screws, you can ensure that your license plates are securely attached to your vehicle, protecting them from theft and avoiding any potential damage or safety hazards. So take the time to research and choose the screws that best meet your needs, giving you peace of mind every time you hit the road.

Table: Common License Plate Screw Sizes

| Screw Size | Metric Equivalent | Common Uses |

|---|---|---|

| M6 | 6mm | Cars, motorcycles, ATVs |

| M8 | 8mm | Trucks, SUVs, RVs |

| #14 | Not applicable | Older vehicles, custom applications |

- Vehicle manufacturer recommendations

- Material and strength

- Anti-theft features

Common License Plate Screw Sizes

When it comes to license plate screws, it’s important to choose the right size for a secure and hassle-free installation. In this section, we will explore three common screw sizes that are commonly used for license plates: M6 screws, M8 screws, and #14 screws.

M6 Screws

M6 screws are one of the most widely used screw sizes for license plates. The “M” stands for metric, and the number “6” refers to the diameter of the screw in millimeters. These screws have a thread pitch of 1.0, which means there is one thread for every millimeter of the screw’s length.

One advantage of M6 screws is their versatility. They can be used on various vehicles, including cars, trucks, motorcycles, and even bicycles. They are also readily available in most hardware stores and online retailers.

To install a license plate with M6 screws, you will need a screwdriver or a socket wrench that fits the screw head. Simply align the holes on the license plate with the holes on the vehicle’s mounting bracket, insert the screws, and tighten them until they are snug. Be careful not to overtighten, as this can damage the threads or strip the holes.

M8 Screws

If you have a larger vehicle or prefer a more robust mounting option, M8 screws may be the ideal choice. Similar to M6 screws, M8 screws are metric screws with a diameter of 8 millimeters. However, they have a larger thread pitch of 1.25, providing a stronger grip.

M8 screws are commonly used on trucks, SUVs, and commercial vehicles due to their ability to withstand heavier loads and vibrations. They are also suitable for license plates that require a more secure attachment, such as those used for off-road vehicles or trailers.

To install a license plate with M8 screws, you will need a socket wrench or a spanner that fits the screw head. Align the holes on the license plate with the mounting bracket, insert the screws, and tighten them firmly. As with M6 screws, be cautious not to overtighten.

#14 Screws

For those looking for an alternative to metric screws, #14 screws offer a viable option. Unlike metric screws, #14 screws are measured in gauge, with a larger number indicating a larger screw diameter.

14 screws are commonly used in the United States and are particularly popular for license plate installations. They are available in various lengths and are compatible with most vehicles. However, it’s crucial to ensure that the screw size matches the vehicle’s mounting holes to avoid any compatibility issues.

To install a license plate with #14 screws, you will need a Phillips head screwdriver or a drill with a suitable screwdriver bit. Align the holes on the license plate with the mounting bracket, insert the screws, and tighten them securely. Take care not to overtighten, as it may lead to damage or stripping of the holes.

In summary, M6 screws, M8 screws, and #14 screws are three common license plate screw sizes that cater to different needs and preferences. Whether you have a standard car or a heavy-duty vehicle, choosing the right screw size ensures a secure and reliable installation. Remember to follow the manufacturer’s recommendations and use proper tools for a successful installation.

Now let’s delve into the next section to learn how to determine the correct license plate screw size.

How to Determine the Correct License Plate Screw Size

Determining the correct license plate screw size may seem like a daunting task, but fear not! With a few simple steps, you’ll be able to find the perfect screws for your license plate. Let’s explore three methods that can help you in this process.

Measuring Existing Screws

One way to determine the correct license plate screw size is by measuring the existing screws on your license plate. This method is especially useful if you’re looking to replace the screws with new ones of the same size.

To measure the existing screws, you’ll need a ruler or a caliper. Start by removing one of the screws from your license plate. Place the ruler or caliper on the shaft of the screw and measure its diameter. Common license plate screw sizes include M6, M8, and #14, which we’ll explore in more detail later.

Once you have the measurement, you can easily find replacement screws of the same size. It’s worth noting that license plate screws are typically metric, so you’ll need to look for screws that match the metric measurement you obtained.

Consulting Vehicle Manual or Manufacturer

Another method to determine the correct license plate screw size is by consulting your vehicle’s manual or contacting the manufacturer directly. Vehicle manuals often contain information about the recommended screw sizes for license plates.

If you don’t have a physical copy of the manual, you can usually find it online on the manufacturer’s website. Look for the section that covers license plate installation or accessories. It may provide specific details about the screw size and type required for your vehicle.

If the manual doesn’t provide the information you need, don’t hesitate to reach out to the manufacturer’s customer service. They will be able to assist you and provide accurate recommendations based on your vehicle’s make and model.

Seeking Professional Assistance

If you’re still unsure about the correct license plate screw size after trying the previous methods, seeking professional assistance is always a reliable option. A mechanic or an automotive specialist will have the knowledge and expertise to help you find the right screws for your license plate.

Visit a local auto repair shop or a dealership and explain your situation to the professionals. They will be able to identify the correct screw size based on your vehicle’s specifications. Additionally, they can also assist you with the installation process if needed.

Remember, it’s crucial to have the correct license plate screw size to ensure a secure and safe attachment. Using the wrong size screws may result in loose or unstable license plates, which can be dangerous while driving.

To summarize, there are three main methods to determine the correct license plate screw size: measuring existing screws, consulting the vehicle manual or manufacturer, and seeking professional assistance. Each method has its advantages, so feel free to choose the one that suits you best. By following these steps, you’ll be well on your way to finding the perfect screws for your license plate.

- Still unsure about the correct license plate screw size? Here are some additional tips to consider:

- Look for online forums or communities where fellow car enthusiasts may have shared their experiences and recommendations regarding license plate screw sizes.

- Consider the material of your license plate and the mounting surface. Different materials may require different screw sizes to ensure a secure fit.

- Don’t forget to check local laws and regulations regarding license plate attachments. Some jurisdictions may have specific requirements for the type and size of screws allowed.

- If you’re replacing license plate screws due to rust or corrosion, it’s advisable to choose stainless steel screws for their durability and resistance to rust.

Remember, taking the time to determine the correct license plate screw size will ensure a proper installation that will keep your license plate securely in place.

Types of License Plate Screw Fasteners

When it comes to securing your license plate onto your vehicle, there are several types of screw fasteners to choose from. Each type has its own unique features and benefits, so it’s important to understand the differences in order to make an informed decision. In this section, we will explore three common types of license plate screw fasteners: self-tapping screws, machine screws, and security screws.

Self-Tapping Screws

Self-tapping screws are a popular choice for license plate installation due to their ease of use and versatility. These screws have a sharp, pointed end that allows them to create their own threads as they are driven into the material. This eliminates the need for pre-drilling pilot holes, saving you time and effort.

One of the advantages of using self-tapping screws is their ability to grip the surface tightly, providing a secure hold for your license plate. They are often made of durable materials such as stainless steel or zinc-plated steel, which makes them resistant to rust and corrosion, ensuring that your license plate stays securely in place even in harsh weather conditions.

Machine Screws

Machine screws are another option for attaching license plates to vehicles. These screws have a uniform diameter and a threaded shaft that requires pre-drilled holes in the license plate and the vehicle’s surface. They are typically tightened using a screwdriver or a wrench.

One of the advantages of using machine screws is their strength and durability. They are designed to withstand high levels of torque, ensuring that your license plate remains securely attached. Machine screws come in various lengths and diameters, allowing you to choose the right size for your specific vehicle and license plate.

Security Screws

If you’re concerned about the theft of your license plate, security screws may be the best choice for you. These screws are specifically designed to deter unauthorized removal, making it more difficult for thieves to steal your license plate.

Security screws often feature unique heads that require special tools, such as a specific screwdriver or a wrench, for installation and removal. Some common types of security screw heads include pin-in-hex, one-way, and tamper-resistant torx. These specialized heads make it nearly impossible for thieves to unscrew the license plate without the proper tools.

In addition to their theft deterrent properties, security screws are typically made of high-strength materials, such as stainless steel or hardened steel, making them resistant to tampering and vandalism.

Table: Comparison of License Plate Screw Fasteners

| Fastener Type | Features | Benefits |

|---|---|---|

| Self-Tapping | Creates its own threads | No need for pre-drilling |

| Durable materials | Resistant to rust and corrosion | |

| ————– | ———- | ———- |

| Machine | Requires pre-drilled holes | Provides strength and durability |

| Various sizes available | Can withstand high levels of torque | |

| ————– | ———- | ———- |

| Security | Unique heads require special tools | Deters theft and tampering |

| Made of high-strength materials | Resistant to tampering and vandalism | |

| ————– | ———- | ———- |

Troubleshooting License Plate Screw Issues

Loose or Stripped Screws

Loose or stripped screws are a common issue when it comes to license plate installation. If your license plate screws are loose, it’s important to address the problem promptly to prevent any further damage or loss of your license plate. One possible solution is to tighten the screws using a screwdriver or a drill with the appropriate screwdriver bit. However, if the screws are stripped and cannot be tightened, you will need to replace them.

To replace loose or stripped screws, you can follow these steps:

- Remove the existing screws by turning them counterclockwise.

- Inspect the screw holes for any damage or corrosion.

- If the screw holes are damaged or corroded, you may need to use a tap and die set to clean and rethread the holes.

- Choose new screws that are the correct size and type for your license plate. Refer to the previous section on common license plate screw sizes for guidance.

- Insert the new screws into the holes and tighten them securely using a screwdriver or a drill.

Rust or Corrosion

Rust or corrosion on license plate screws can not only make them difficult to remove or install, but it can also weaken the screws and compromise their effectiveness. If you notice rust or corrosion on your license plate screws, it’s important to take action to prevent further damage.

To remove rust or corrosion from license plate screws, you can try the following steps:

- Apply a penetrating oil, such as WD-40, to the screws and allow it to sit for a few minutes.

- Use a wire brush or a scrubbing pad to gently scrub away the rust or corrosion.

- If the rust or corrosion is stubborn, you can also try using a rust dissolver or a mixture of vinegar and baking soda.

- Once the rust or corrosion is removed, dry the screws thoroughly to prevent future rusting.

If the rust or corrosion has caused significant damage to the screws, it is recommended to replace them with new ones. Refer to the previous section on common license plate screw sizes for guidance on choosing the correct replacements.

Difficulty in Removal or Installation

Sometimes, license plate screws can become extremely difficult to remove or install due to various reasons such as rust, over-tightening, or improper alignment. If you’re facing difficulty in removing or installing license plate screws, here are a few tips to help you overcome the challenge:

- Apply a penetrating oil, such as WD-40, to the screws and allow it to sit for a few minutes. This can help loosen the screws and make them easier to remove.

- If the screws are stuck due to rust or corrosion, follow the steps mentioned in the previous section to remove the rust or corrosion.

- Use the appropriate tools for the job. A screwdriver or a drill with the correct screwdriver bit can make the removal or installation process much easier.

- Ensure proper alignment of the license plate and the screw holes. Misalignment can cause resistance and make it difficult to insert or remove the screws. Adjust the position of the license plate as needed.

- If all else fails, seeking professional assistance from a mechanic or an automotive specialist may be the best option. They have the experience and tools necessary to handle stubborn screws and ensure a proper installation.

Remember, it’s important to address any issues with license plate screws promptly to ensure the safety and security of your license plate. By following these troubleshooting tips, you can overcome common problems and ensure a successful installation or removal of license plate screws.

Tips for Installing License Plate Screws

When it comes to installing license plate screws, there are a few key tips that can help ensure a successful and secure installation. By following these tips, you can avoid common issues such as loose screws, misalignment, and difficulty in removal or installation. In this section, we will discuss three important aspects of installing license plate screws: using proper tools, applying correct torque, and ensuring proper alignment.

Using Proper Tools

Using the right tools for the job is essential when it comes to installing license plate screws. Here are some tools that you may find helpful:

- Screwdriver: A screwdriver is the most common tool used for installing license plate screws. Make sure to choose a screwdriver that matches the type of screw head you are working with. Common screw head types include Phillips, flathead, and Torx.

- Socket wrench: If you prefer to use a socket wrench, make sure to select the correct size socket that fits the screw head. This can help provide a more secure grip and make the installation process easier.

- Power drill: For faster and more efficient installation, you can use a power drill with a screwdriver bit. However, be cautious not to overtighten the screws, as this can strip the threads or damage the license plate.

Applying Correct Torque

Applying the correct torque is crucial to ensure that the license plate screws are properly secured without causing any damage. Torque refers to the amount of rotational force applied to a screw or bolt. Here are some important points to consider when applying torque:

- Follow manufacturer recommendations: Consult the vehicle manufacturer’s guidelines or the license plate screw manufacturer’s instructions for the recommended torque specifications. These specifications may vary depending on the type of vehicle and the material of the license plate.

- Use a torque wrench: To achieve the recommended torque, it is advisable to use a torque wrench. This tool allows you to accurately measure and control the amount of force applied to the screws. Set the torque wrench to the recommended value and tighten the screws accordingly.

- Avoid overtightening: While it’s important to ensure the screws are securely tightened, be cautious not to overtighten them. Over-tightening can lead to stripped threads, cracked license plates, or even damage to the vehicle’s body. Remember, the goal is to achieve a snug fit, not to exert excessive force.

Ensuring Proper Alignment

Proper alignment of the license plate is not only crucial for aesthetics but also for avoiding potential issues such as obstructed visibility or license plate loss. Here are a few tips to ensure proper alignment:

- Measure and mark: Before installing the screws, measure and mark the desired position for the license plate. This will help you align the plate correctly, ensuring that it is centered and level. Use a measuring tape or ruler to achieve accurate measurements.

- Align with mounting holes: Most license plates come with pre-drilled mounting holes. Align the holes on the license plate with the corresponding holes on the vehicle’s bumper or license plate bracket. This will help maintain proper alignment and prevent the plate from shifting or coming loose.

- Double-check alignment: Once the screws are partially tightened, double-check the alignment of the license plate. Stand back and visually inspect the plate from different angles to ensure it is straight and properly positioned. Make any necessary adjustments before fully tightening the screws.

In conclusion, installing license plate screws may seem like a simple task, but paying attention to details can make a significant difference in the overall outcome. By using proper tools, applying correct torque, and ensuring proper alignment, you can achieve a secure and aesthetically pleasing installation. Remember to consult the vehicle manual or seek professional assistance if needed, and always prioritize safety and adherence to manufacturer recommendations.